Several Common Sense to Know for Wiring Terminals

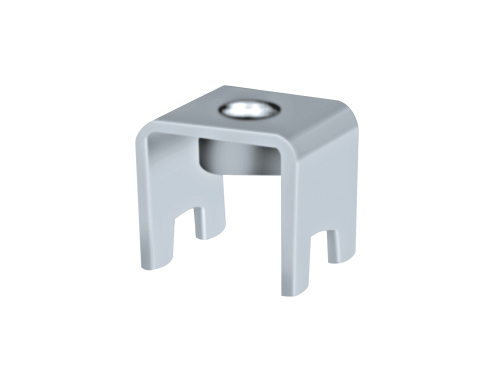

Screw connected printed circuit board terminals have always played an important role in the electronic industry and have now become an important component of printed circuit boards. Its structured design takes into account the characteristics of convenient wiring and reliable screw connections.

The printed circuit board wiring terminals for spring connection are divided into two types: pull-back spring connection and butterfly spring connection. The pull-back spring terminal and screw terminal can replace each other, greatly increasing flexibility.

The IDC stripping free quick wiring terminal can achieve quick connection of insulated wire without using any tools. Pull the opening aid rod to push the wire into the blade and cut off the insulation skin to achieve airtight connection. This wiring method saves up to 60% of the wiring time and is certified for use in Ethernet wiring (Class 5 cables).

Regardless of the connection method of the wiring terminal, they all have the following advantages:

1. Large wiring capacity, suitable for various wiring requirements.

2. The shell of the wire clamp body is mechanically decoupled from the welding needle, that is, because the shell of the wire clamp body is not connected to the welding needle as a whole, the torque when tightening the screw will not be transmitted to the welding point.

3. The welding needle is square in shape, and the end shrinks and becomes thinner. When inserting welding holes, it can prevent arbitrary rotation. Dissolve the welding fluid into the welding hole.

4. The welding needle is made of copper alloy, and it is free of dirt, ensuring the long-term reliability of welding.

5. Tin plated solder pins for easy soldering.

6. With heat dissipation channels.

7. The end of the welding needle shrinks and becomes thinner, making it easy to install.

Users can not only choose different parameters according to their needs, such as needle position, needle pitch, etc., but also choose different wiring directions. In practical applications, the layout of components (such as the position of the PCB in the casing) often limits the wiring terminals of printed circuit boards. The printed circuit board wiring terminals that can provide multiple different wiring directions undoubtedly have important practical significance: horizontal, vertical, diagonal, and front. The more choices provided, the greater the assistance to practical operations.

Printed circuit board wiring terminals can even be provided for multi-layer wiring (1 to 4 layers) wiring terminals (MKDS... to MK4DS...). The arrangement between layers is very compact, and the needle spacing is staggered by half in the vertical direction. This type of wiring terminal fully meets the design requirements of compact layout and space saving.

The screw connection terminal can be compatible with the spring connection terminal. The so-called compatibility means that the two can be interchanged without changing the layout of the printed circuit board. This greatly improves the adaptability of the product and greatly reduces costs.

Equipped with cold pressing head, pre installation, and special housing colors - special models of terminals can be provided according to user requirements. Professionally produce every wiring terminal product to serve society.

Mobile website

Mobile website Scan and follow

Scan and follow